- Home

-

Product

-

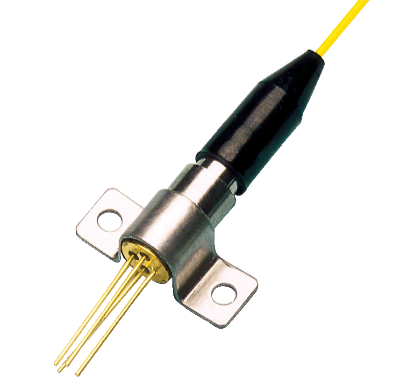

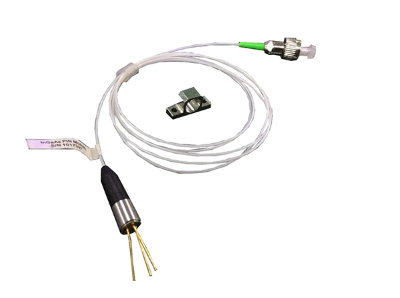

660nm 50mW Coaxial Laser Diode

660nm 50mW Coaxial Laser Diode -

1577nm EML Diode Module

1577nm EML Diode Module -

CWDM Butterfly laser diode

CWDM Butterfly laser diode -

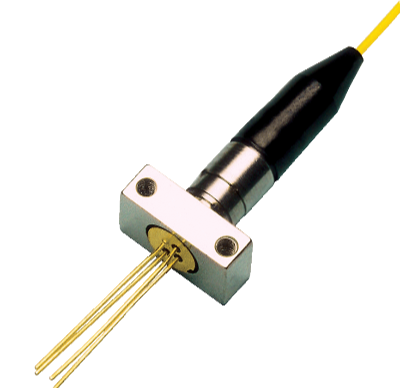

2.5G 1650nm Coaxial Laser Diode Module

2.5G 1650nm Coaxial Laser Diode Module -

1.25G~10G 1550nm Coaxial Laser Diode Module

1.25G~10G 1550nm Coaxial Laser Diode Module -

1.25G~10G1310nm Coaxial Laser Diode Module

1.25G~10G1310nm Coaxial Laser Diode Module -

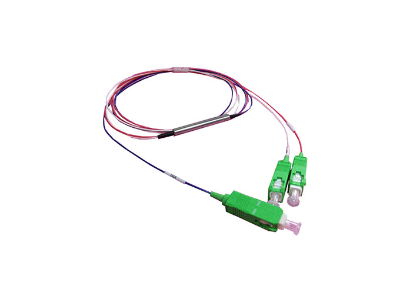

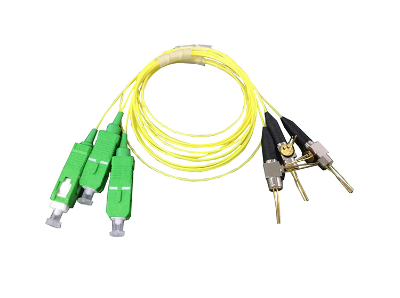

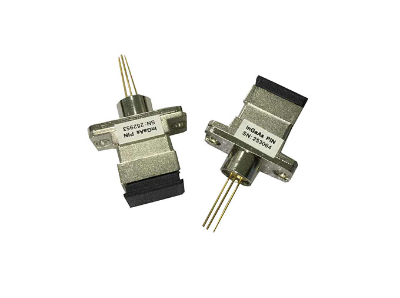

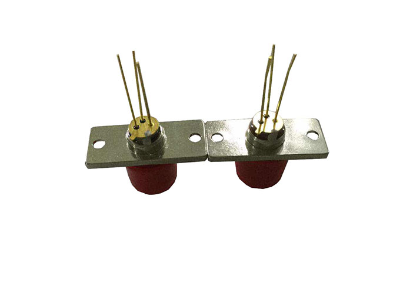

Dual Photo detector Module

Dual Photo detector Module -

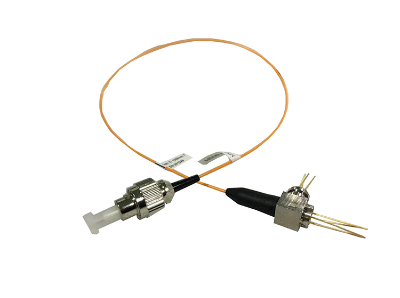

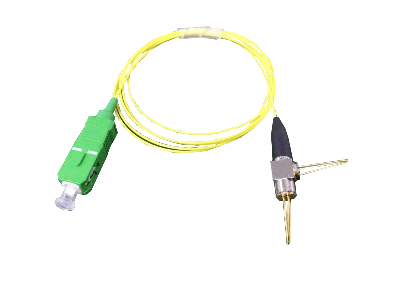

1000um Coaxial InGaAs PIN Detector

1000um Coaxial InGaAs PIN Detector -

500um Coaxial InGaAs PIN Detector

500um Coaxial InGaAs PIN Detector -

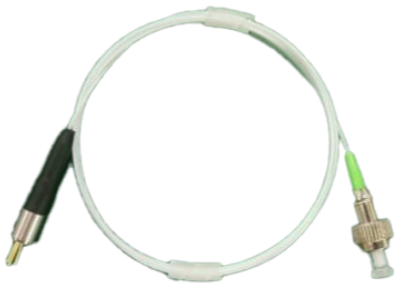

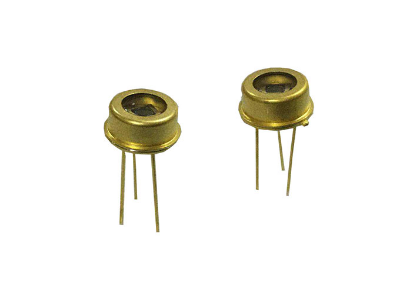

75um InGaAs Photo Diode

75um InGaAs Photo Diode -

300um Coaxial InGaAs PIN Detector

300um Coaxial InGaAs PIN Detector -

3mm&5mm&8mm Photo Detector

3mm&5mm&8mm Photo Detector -

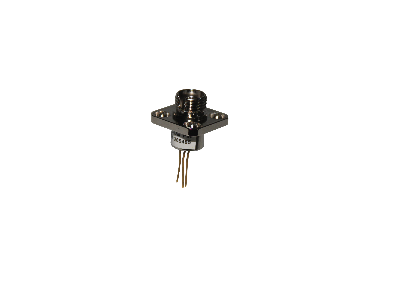

Si APD TO-CAN Module

Si APD TO-CAN Module -

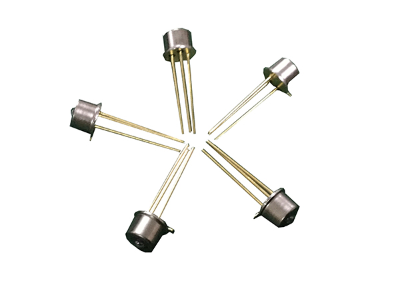

GaAs PIN PD TO-CAN

GaAs PIN PD TO-CAN -

1000um InGaAs PD TO-CAN

1000um InGaAs PD TO-CAN -

2.5G InGaAs PD TO-CAN

2.5G InGaAs PD TO-CAN -

2000um InGaAs PIN Detector TO-CAN

2000um InGaAs PIN Detector TO-CAN

-

- Application

- About US

- News

- Support

sales@o-send.com,lvdx@o-send.com

重庆市经济开发区茶园梅花路1号3栋2座